|

|

TIME FOR A NEW LOOK AT MANUFACTURING

AND HIGH-TECH

The Providence

Business News, May, 1997

How far has Rhode Island's manufacturing employment base fallen? What must we do to

maintain a stable employment base in manufacturing? Other than the silly topic of whether

manufacturing here is dead or alive, these are the two questions that are discussed most

frequently. Everyone seems willing to venture answers to these questions. I find it

intriguing that even the most influential persons in this state, those who directly

influence policy, continue to approach these with a "traditional" perspective

that lost its relevance ten years ago when Rhode Island became a service and

information-based economy. If we are to meaningfully assess the performance of Rhode

Island's manufacturing sector, we must begin to address questions such as these with a

"non-traditional" perspective.

As a first step in this process, it is necessary to question the viability of the

existing employment classifications upon which our assessments of manufacturing employment

are based. The Standard Industrial Classification (SIC) code categorizes employment by a

series of two, three and four-digit breakdowns. As anyone familiar with SIC codes will

attest, the amount of detail allowed for the manufacturing sector is noticeably greater

than for the service sector. This shouldn't come as much of a surprise since these

classifications were formulated during our nation's manufacturing era, as the

"Industrial" in SIC name code attests. But, while these classifications may have

served us well during the manufacturing era, today they are showing signs of age.

Should we limit our classification of manufacturing activity exclusively to

"goods"? If we do, then the existing "wisdom" on the performance of

our manufacturing sector is valid. Let me argue that we must be more realistic and extend

the definition of manufacturing activity to include both goods and services.

Manufacturers produce both final goods for consumers and inputs for other firms. Just

as this classification is not restricted to "final goods," we need to extend the

definition of "manufactured inputs" to include both goods and services. Today,

manufacturing firms that utilize computer inputs tend to rely far more on personal

computers than on mainframes. So, to produce its product, a hypothetical firm might use

processed steel as an input, which is classified as "manufactured" along with

data processing and computer programming services which are listed under the SIC category

"Business Services." Can we manufacture services? I believe we can. Business

services should be viewed as a valid form of production. The importance of this should be

obvious: an increasing part of the wealth generated during the "information age"

is related to the creation and processing of data.

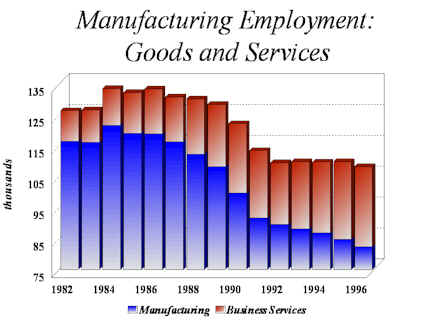

If we broaden the definition of manufacturing to include the production of both goods  and services, then, the

trend in Rhode Island manufacturing employment is very different from what is commonly

believed. For well over a decade, the number of jobs in manufacturing has been falling

while business service employment has been rising. The result, as the graph shows, is that

"Manufacturing Goods and Services" employment has remained constant throughout

this entire recovery. and services, then, the

trend in Rhode Island manufacturing employment is very different from what is commonly

believed. For well over a decade, the number of jobs in manufacturing has been falling

while business service employment has been rising. The result, as the graph shows, is that

"Manufacturing Goods and Services" employment has remained constant throughout

this entire recovery.

This brings me to the second question I posed, concerning the requirements for

maintaining a stable manufacturing employment base. Ironically, some manufacturing

employees, those employed by "temp" agencies, are classified under business

services. As a result, we don't know the actual number of manufacturing employees in Rhode

Island. We therefore don't know when manufacturing employment peaked, how much

manufacturing employment has fallen since that peak, or the manufacturing job change since

the present recovery began. What we do know is that in our present low-inflation climate,

manufacturing firms must cut costs to remain competitive. This has compelled surviving

firms to incorporate labor-saving technology into production, which, as its name implies,

has reduced our manufacturing employment base. So, the "good old days" are truly

gone: to maintain a stable manufacturing employment base, it is no longer enough to retain

the same number of manufacturing firms. We need existing firms to expand and new firms to

locate here.

This reclassification of manufacturing activity has important implications for public

policy. High tech services and manufacturing must no longer be viewed as distinct or

mutually exclusive. Policy recommendations should encourage both areas simultaneously.

Just as roads and bridges provide "external economies" for businesses, which has

historically provided a justification for public investment in this area, knowledge and

technology also generate external economies. We should no longer make separate sets of

policy recommendations for manufacturing and "high tech." Instead, this pair

should be viewed as our primary "cluster."

by Leonard Lardaro |